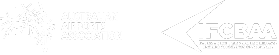

Enhanced ability to make informed decisions based on comprehensive, up-to-date data.

Identification and reduction of bottlenecks, waste, and inefficiencies in the manufacturing process

Identification and reduction of bottlenecks, waste, and inefficiencies in the manufacturing process

Immediate insight into production processes, inventory levels, and supply chain status.

Continuous monitoring of product quality and performance metrics, leading to higher customer satisfaction.

Chief Financial Officer,

Bradnam’s Windows & Doors

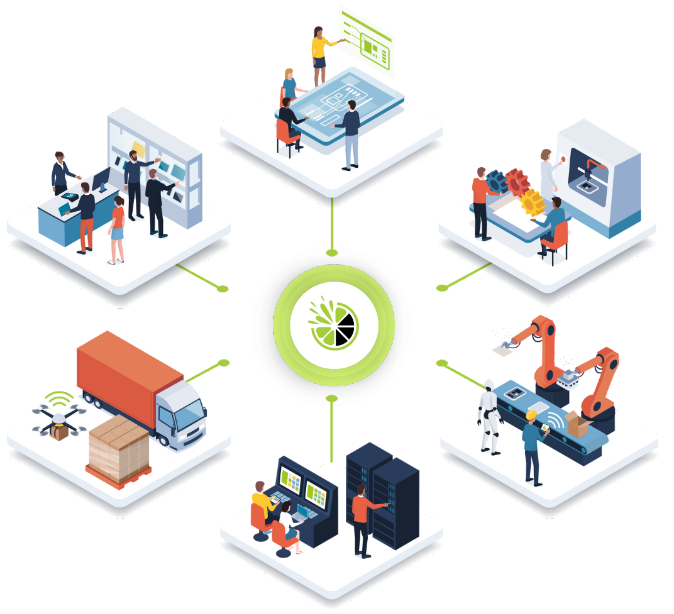

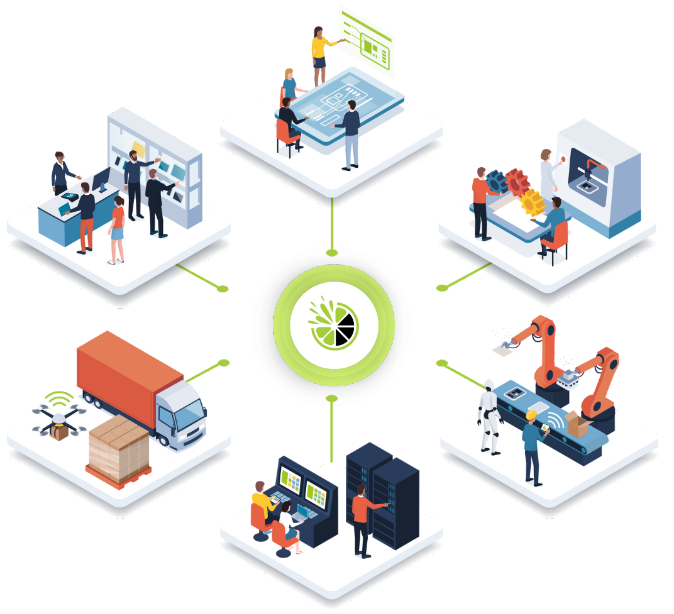

You don’t need to replace your systems, you can build the reporting you need and find answers by tapping into existing systems and joining data into a central source of truth with Lime.

Swap spreadsheet mayhem for visual reports and’ drill-down’ features to simplify data

Production volume, Downtime, Cycle Time, Overall Equipment Effectiveness, Scrap Rates.

Maintenance Schedule Adherence, Breakdown Frequency, Repair Times, Equipment Reliability, Preventive Maintenance Compliance.

Production volume, Downtime, Cycle Time, Overall Equipment Effectiveness, Scrap Rates.

Defect Rates, Inspection Outcomes, Return Rates, Compliance Rates, CAPA Status.

Cost of Goods Sold, Operating Margins, Revenue by Product Line, Budget Variance, Capital Expenditure vs. Operating Expense.

“Proud to be members of AMTIL (The Australian Manufacturing Technology Institute Limited (AMTIL) is the peak national body, a manufacturing industry association in Australia”

See how Lime Intelligence can transform your manufacturing business today.

Try a free demo and embark on a path to data-driven brilliance.